gthh

Jetboaters Captain

- Messages

- 425

- Reaction score

- 420

- Points

- 212

- Location

- Buffalo, NY

- Boat Make

- Yamaha

- Year

- 2007

- Boat Model

- AR

- Boat Length

- 23

Ooops.

Something you never want to hear from a Surgeon during an operation while you are on the operating table or your wife as she is mowing the lawn with a 54” zero turn mower around our boat!

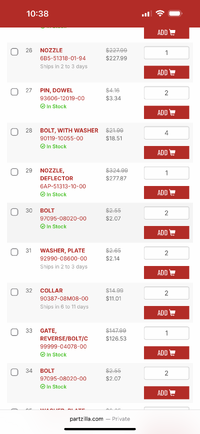

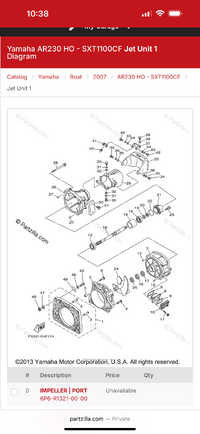

Long story short-she bumped the port side jet and broke the control deflector arm attachment and possibly the control cable support strut.

I thought I would canvas the group and garner any suggestions (and sympathy) before a trip to partzilla.

This may be an opportunity to upgrade (guilt is like an open check book!-I know, that’s just mean-just getting over the trauma-I guess). What do you think Will Owen????

The 2007 AR230 never cost me a dime in repairs so investing in some improvements would not be out of the question.

Not a good premature end to the boating season but possibly a chance to give back to a boat that has given so much to us over the years.

Thanks

Something you never want to hear from a Surgeon during an operation while you are on the operating table or your wife as she is mowing the lawn with a 54” zero turn mower around our boat!

Long story short-she bumped the port side jet and broke the control deflector arm attachment and possibly the control cable support strut.

I thought I would canvas the group and garner any suggestions (and sympathy) before a trip to partzilla.

This may be an opportunity to upgrade (guilt is like an open check book!-I know, that’s just mean-just getting over the trauma-I guess). What do you think Will Owen????

The 2007 AR230 never cost me a dime in repairs so investing in some improvements would not be out of the question.

Not a good premature end to the boating season but possibly a chance to give back to a boat that has given so much to us over the years.

Thanks